BLOCK CASE PACKER

BLOCK CASE PACKER PRESENTATION

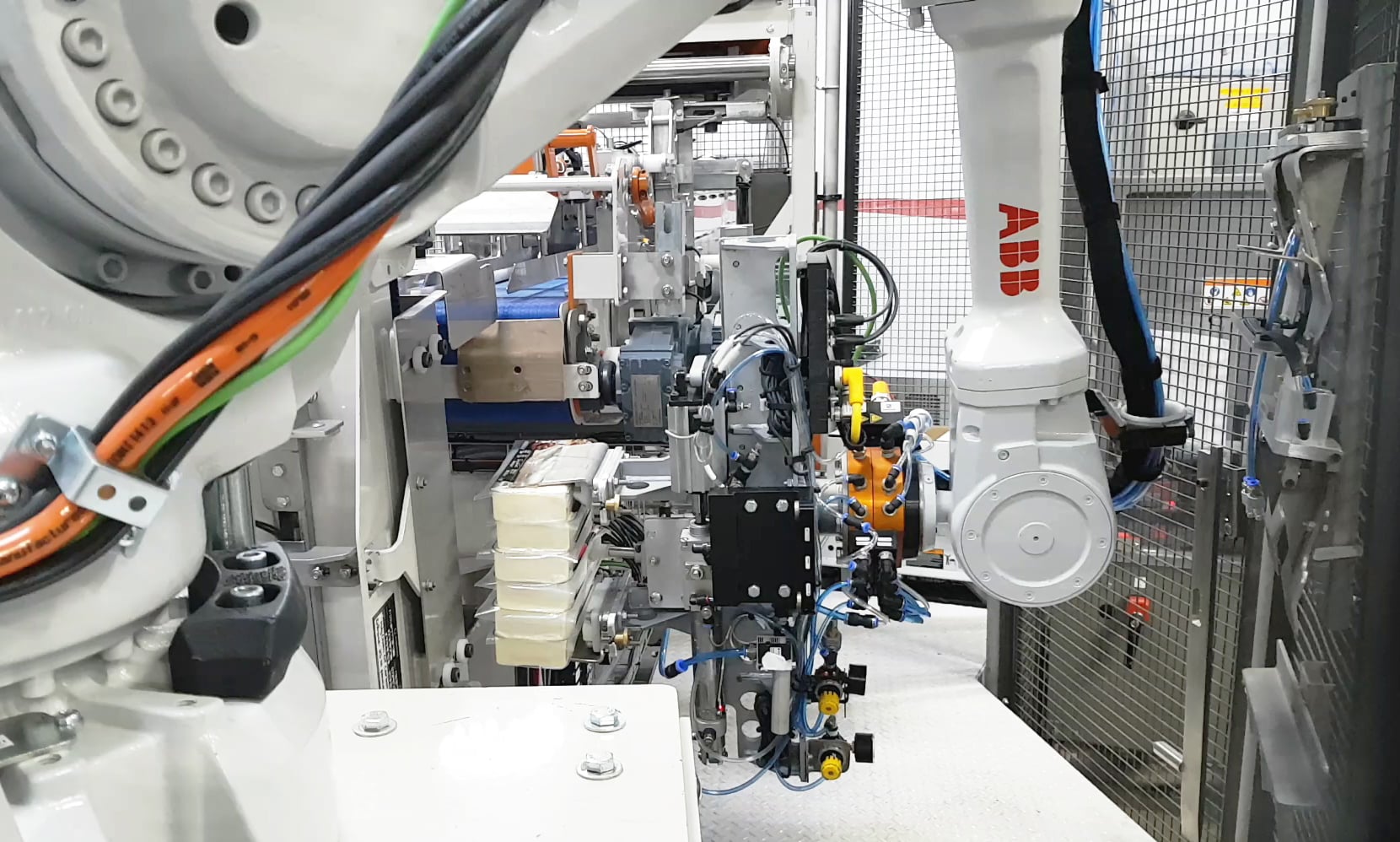

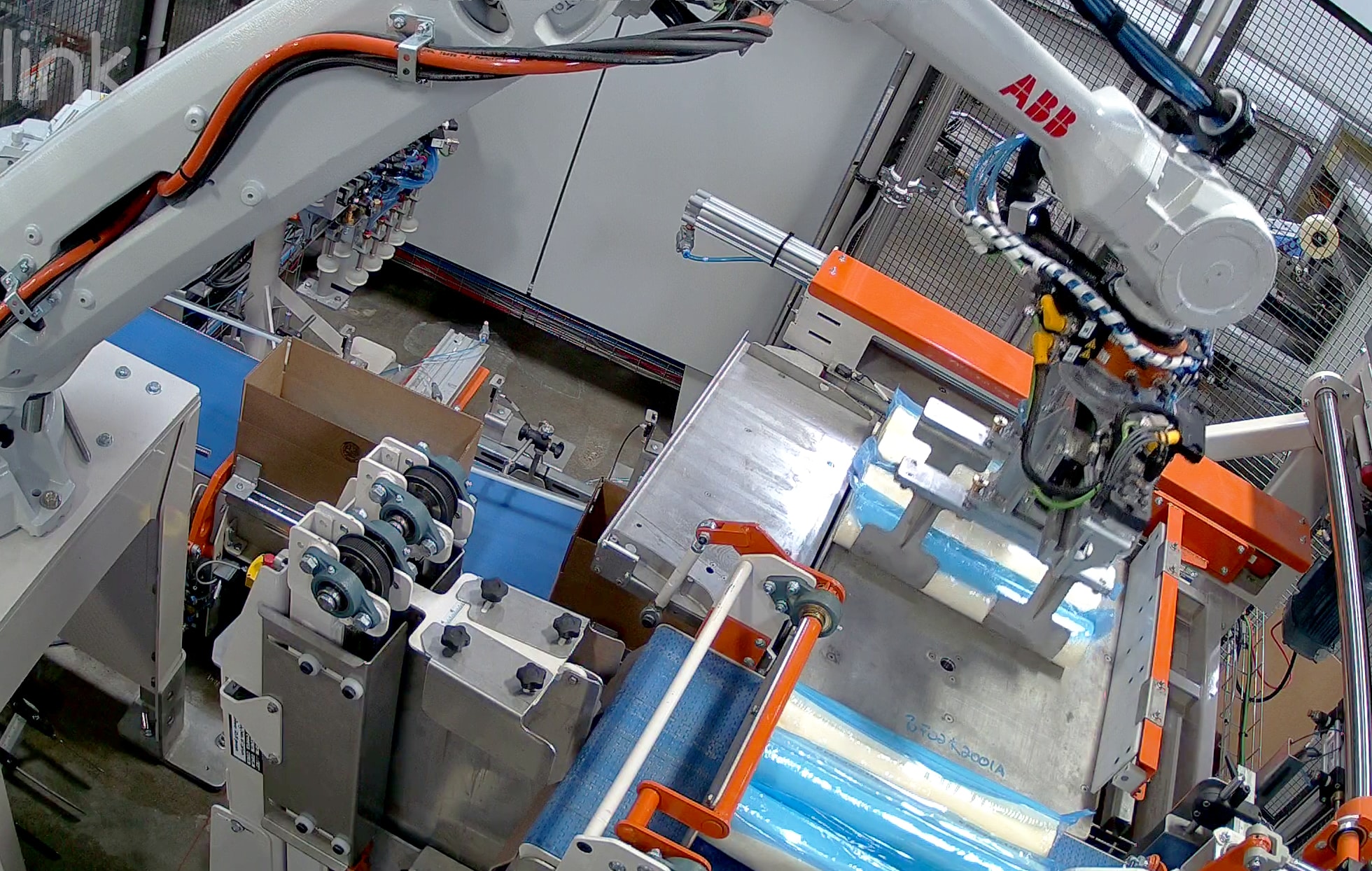

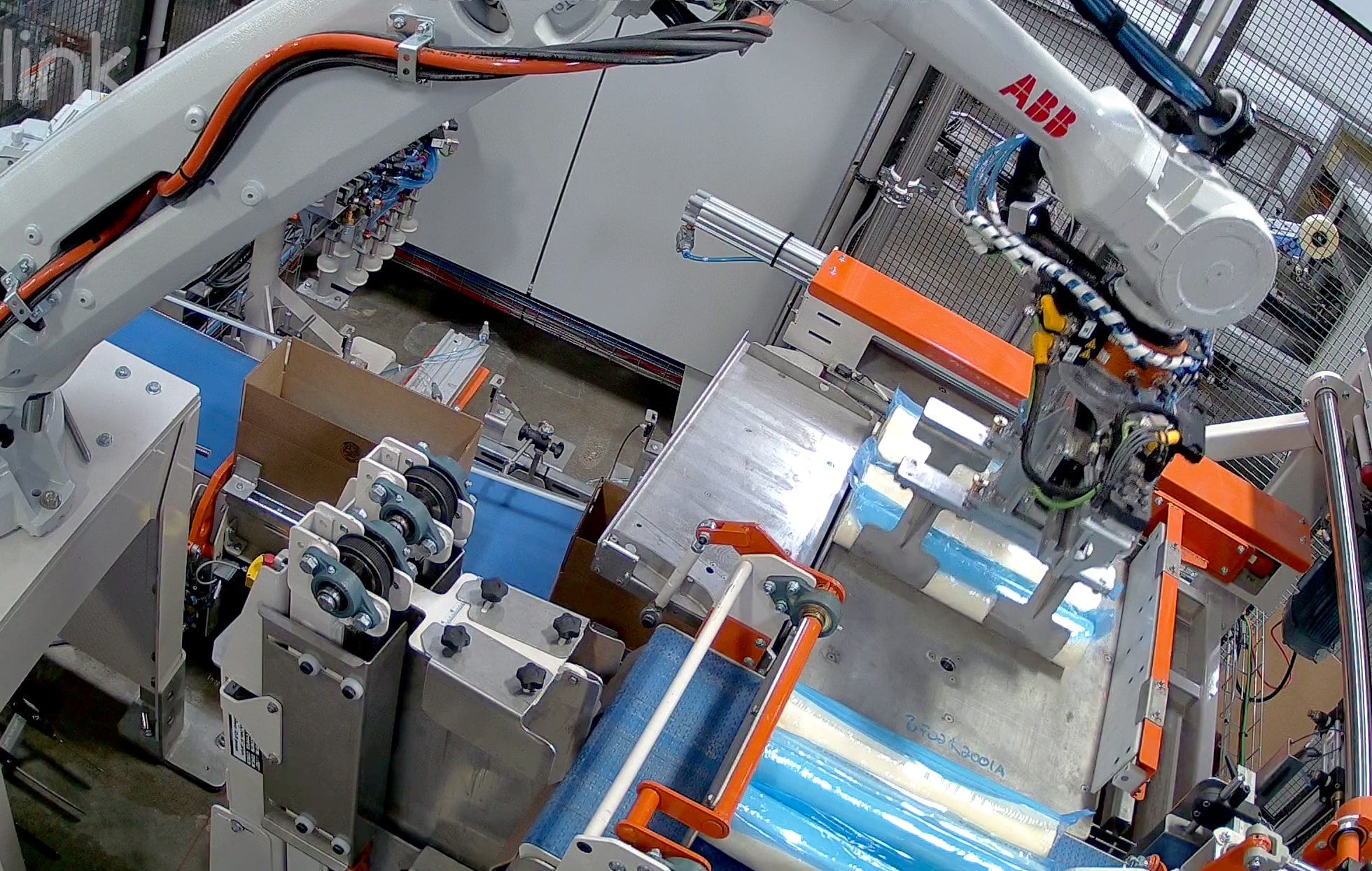

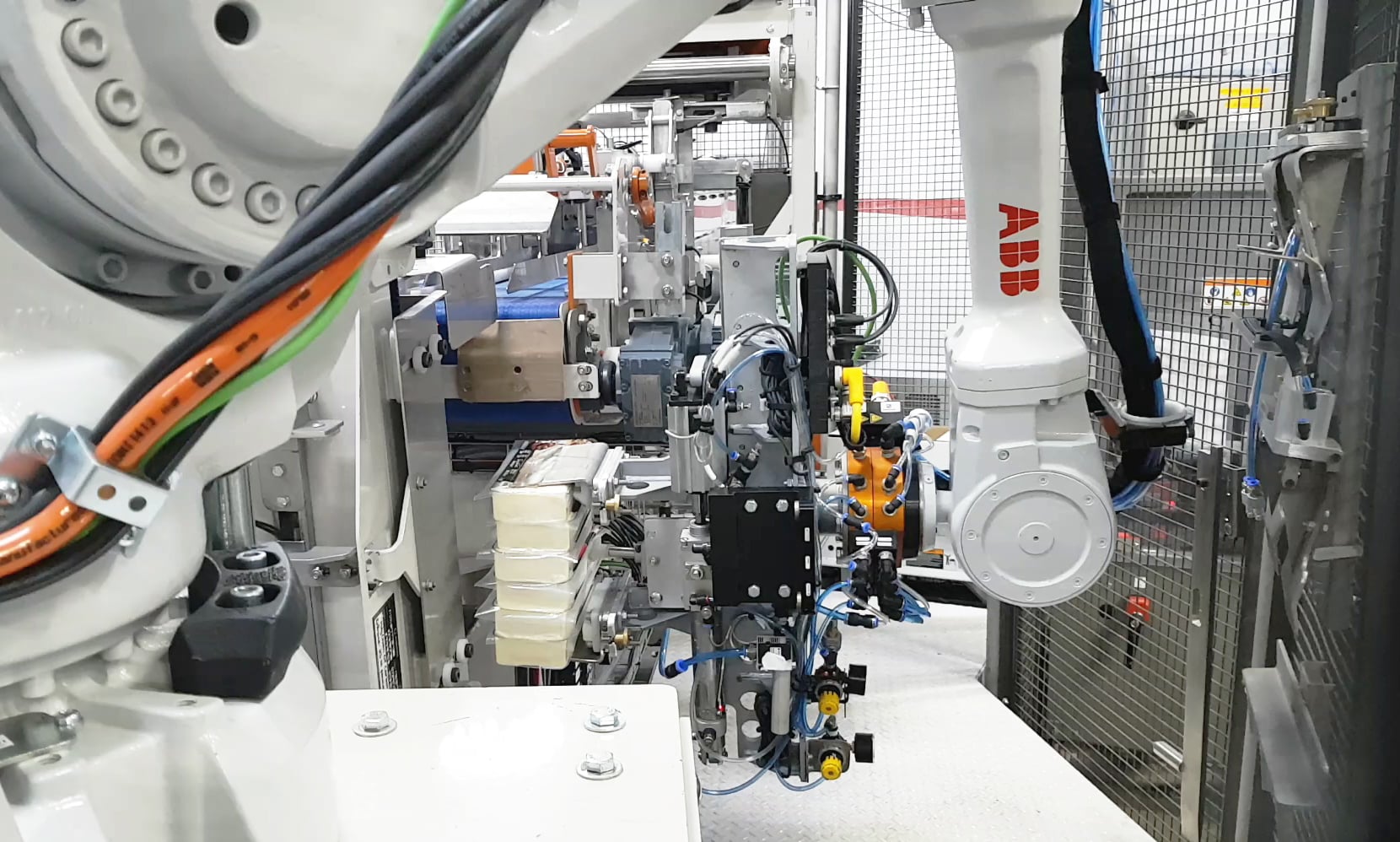

Our case packer for block is a scalable solution that can be adapted to a large variety of products. The case packing equipment cell can be adjusted to respond to a wide range of evolving elements such as speed rates, patterns and block formats.

The gripping system of our robotic case packer for block is tailor-made to ensure it can handle a number of blocks simultaneously while positioning them in cases with no damage to either products or cases. The system can position blocks stacked flat or on the side.

Optimized dimensions for the case packing equipment cell means it requires only limited floor space thanks to its slim build. A form-and-seal unit can be added to the robotic case packer for block to obtain a fully automated case packing solution.

BLOCK CASE PACKER ADVANTAGES

![]() Adapted grippers for precise product handling.

Adapted grippers for precise product handling.

![]() Highly flexible system designed for a variety of applications.

Highly flexible system designed for a variety of applications.

![]() Stacking patterns of blocks flat or on the side.

Stacking patterns of blocks flat or on the side.

![]() User-friendly interface that allows quick and easy production adjustments.

User-friendly interface that allows quick and easy production adjustments.

![]() Great variety of available options and configurations.

Great variety of available options and configurations.

![]() Optimized floor space.

Optimized floor space.

![]() Speed : 100 blocks per minute.

Speed : 100 blocks per minute.

BLOCK CASE PACKER OPTIONS

![]() Fully automated case form-and-seal unit.

Fully automated case form-and-seal unit.

![]() Labeling on the crate.

Labeling on the crate.

![]() Case closing system.

Case closing system.

![]() Metal detector.

Metal detector.

![]() Scale conveyor.

Scale conveyor.

![]() Discarding system.

Discarding system.

![]() Second robot for higher production speed.

Second robot for higher production speed.

BLOCK CASE PACKER DATA SHEET

|

Robot : |

ABB IRB360 – IRB4600 |

|

Speed : |

Max capacity is 100 blocks per minute / robot |

|

Gripper : |

Single or multiple pneumatic or mechanical grip |

|

Feeding : |

1 to 2 production lines max |

|

Power : |

575 VAC & 120V/1/60 15A |

|

Build : |

Painted steel – (stainless steel optional) |

|

Working temperature: |

1°C to + 45° C |

|

Configuration : |

Different configurations available |

ANY QUESTIONS ?

OUR TEAM WILL BE HAPPY TO ANSWER THEM FOR YOU

© 2024 Robovic Inc. All rights reserved