BIG BAG HANDLING : THE DIFFERENCE BETWEEN THE FULLY AUTOMATIC AND SEMI-AUTOMATIC SYSTEM !

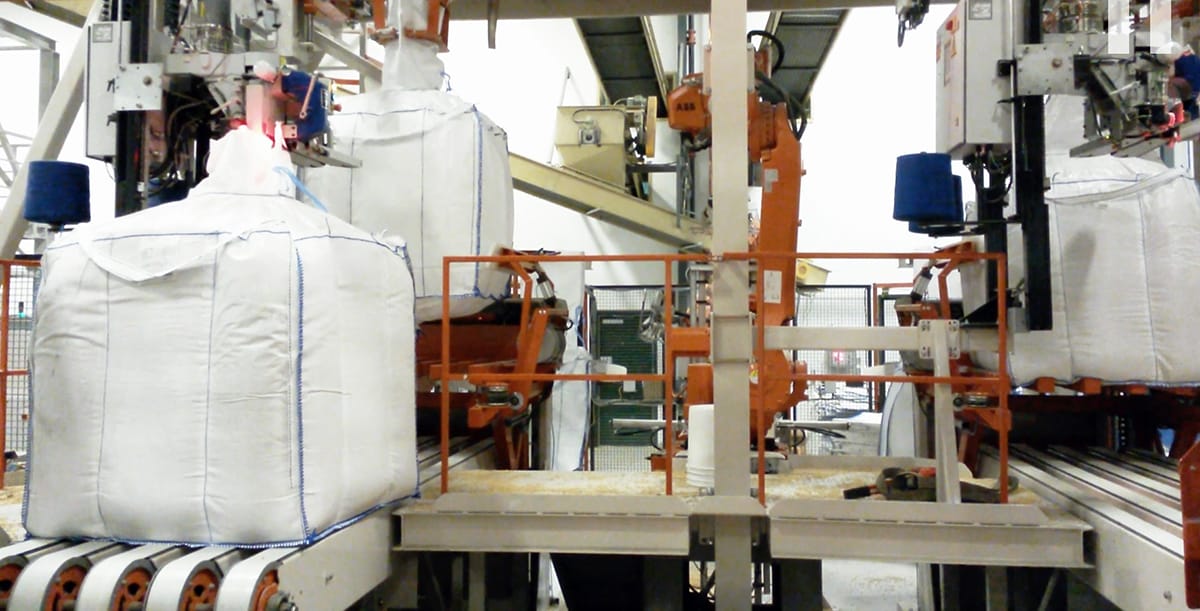

The big bag handling machine is a solution that executes the filling of large quantities of bulk products into large flexible bags in an ergonomic, efficient manner and with the desired level of automation.

Companies working in the field of powders such as agri-food, chemicals, aggregates, and also granular products can be equipped with this type of system.

There are 2 versions of big bag handling, the semi-automatic system, the most common traditional model on the market and the fully automatic robotic system dedicated to high-speed production.

Usually, there is confusion about these two different solutions. The semi-automatic system is often associated with the fully automatic because the integrators present their filling solutions and manual hanging as being completely automatic, yet there is human intervention involved in this process.

In this article, we will compare these two systems to determine the difference and benefits of each.

The semi-automatic big bag handling is a system that requires an operator to hook and close the bag.

The performance of this system varies according to the solutions as they are generally tailor-made to satisfy the customer’s specific requirements. Generally, these solutions fill bags ranging from 500 kg up to 1500 kg per bag and can reach a production rate of up to 30 bags per hour. The Robovic semi-automatic big bag handling system distinguishes itself by its efficient and ergonomic configuration for optimized production rates. The operator is able to position the bags easily and quickly by hooking the four straps directly to the front of the system therefore preventing the operator from leaving his work station.

The work station is arranged so that the operator can close the filled bag while the filling operation continues. The bag is lifted automatically and the operator can hook the following bag to maximizing the filling rates.

Unlike the semi-automatic system, the automatic big bag bagger does not require an operator for the system. Totally automatic, it executes bulk bag filling operations from the beginning right to the end process.

The addition of a second robot to the system makes it unique, in fact, picking up the bags directly from a stack rather than from a roll, significantly reduces the packaging costs.

This automatic solution, fully developed by Robovic, is dedicated to high-speed production. It is capable of filling 500 kg to 2 ton bags at a rate of 30 to 55 totes / bulks per hour.

Whether fully automatic or semi-automatic, our big bag handling systems are equipped with a sequence of movements and vibrations which positions and levels the product in order to obtain maximum stability once the bag is filled.

Our filling solutions are built with extremely durable components that can integrate many options such as a wrapping system for better compression of bulk bags or labeling for quick big bag identification.

To conclude, a big bag handling system offers many advantages, especially improving working conditions and employee safety, high and constant production capacity and finally earnings saved related to workforce reduction.

If you would like to know more about our filling systems

Read more

ROBOVIC will be present at ADM/PACKEX’s show in Montréal 2024

N’hésitez pas à venir nous rencontrer sur notre kiosque

Integrated pallet wrapper : 3 essential elements to consider for packaging products

Selecting the right industrial wrapper when integrating a palletizer is essential, discover the advantages of integrated wrapping…

Palletizing gripper : why control product deposit rather than letting it drop ?

Discover the advantages of depositing the products on an angle with the palletizing gripper developed by ROBOVIC…

© 2021 Robovic Inc. All rights reserved