M3000 & M3550 – POUCH BAGGER

M3000 & M3550 BAGGERS PRESENTATION

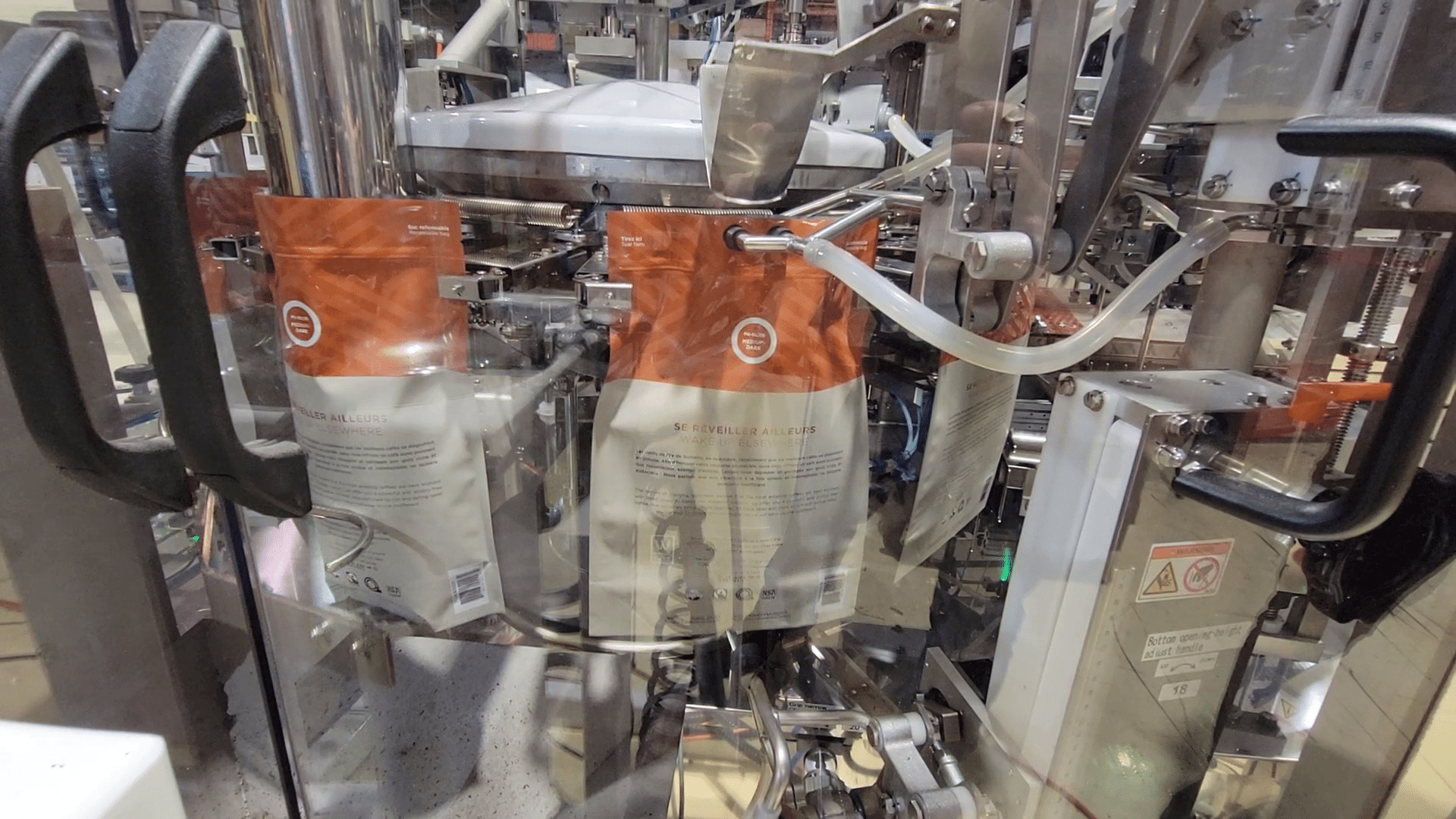

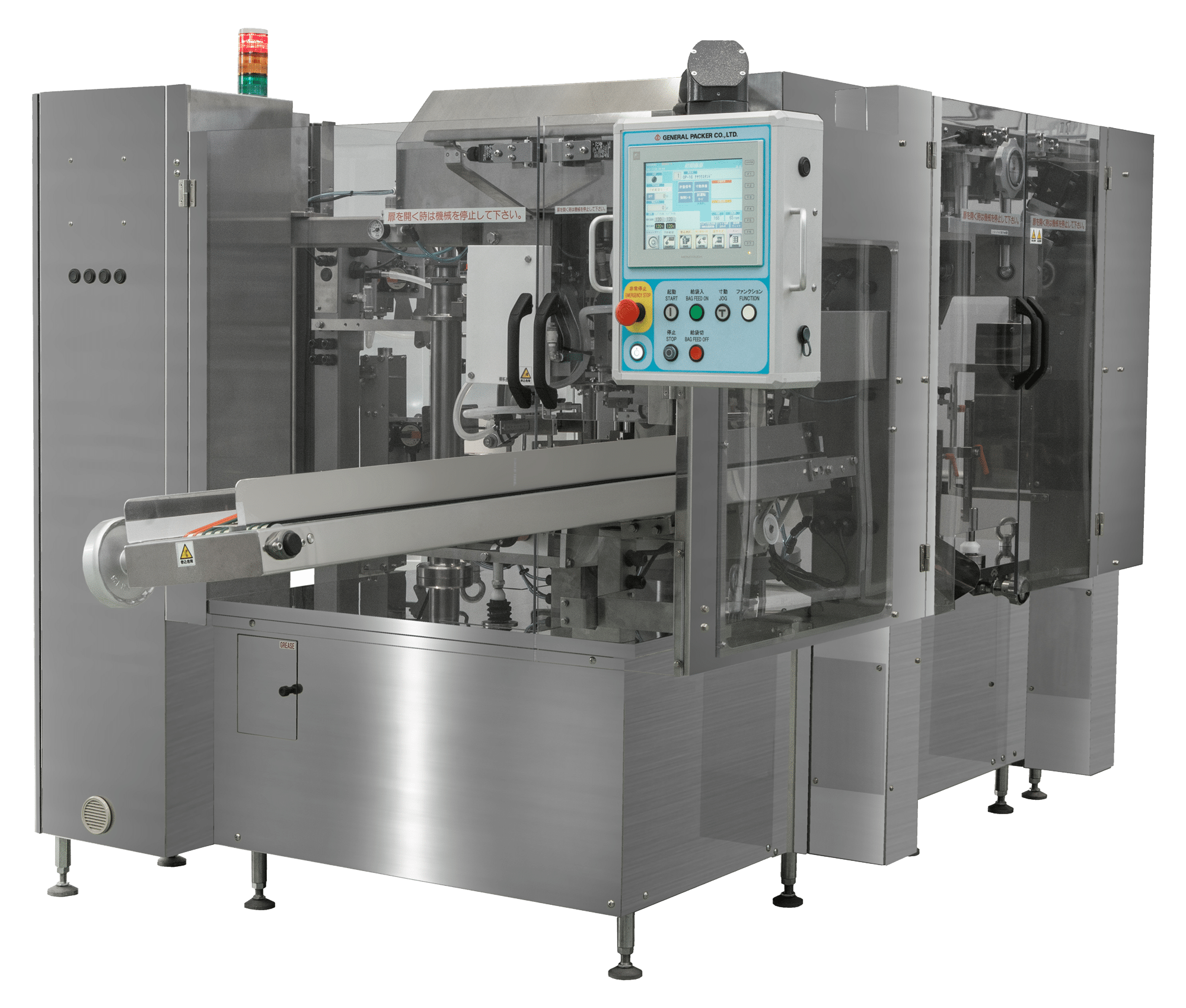

The preformed bag packaging machines M3000 & M3550 from General Packer are proven systems, recognized for their reliability, with over 700 units of just these models installed worldwide over the past 7 years and over 10,000 General Packer machines installed over 63 years since the company was founded.

These models stand out for their 10 base station technologies, while most of their competitors typically offer 8. These two additional stations are positioned between the filling and sealing stages. This layout provides three times more space and time to allow the product to stabilize and facilitate additional functions such as secondary filling station, Nitrogen flushing, etc.

These machines embody the philosophy of “quality through precision.” Every component, every feature is meticulously designed to ensure optimal performance and reliable results. They incorporate servo motor technologies that automatically adjust multiple parameters, thus offering adjustment flexibility to precisely handle different products or types of pouches/bags.

Each step of the bagging process is carefully checked and continuously adjusted to ensure precise and consistent operation. The M3000 & M3550 models also offer great flexibility, adapting to a wide variety of applications such as powder, pet food, various types of snacks, and other solid materials.

M3000 & M3550 POUCH BAGGERS ADVANTAGES

![]() 10 basic stations for optimized productivity.

10 basic stations for optimized productivity.

![]() Continuous checking of the bagging cycle at each stage for precise product handling.

Continuous checking of the bagging cycle at each stage for precise product handling.

![]() Increased nitrogen control to preserve product quality and shelf life.

Increased nitrogen control to preserve product quality and shelf life.

![]() Intuitive interface for easy production changes in less than 90 seconds (depending on the product).

Intuitive interface for easy production changes in less than 90 seconds (depending on the product).

![]() Bolt-free design for easy cleaning process.

Bolt-free design for easy cleaning process.

![]() Production rate of up to 65 bags/min.

Production rate of up to 65 bags/min.

M3000 & M3550 POUCH BAGGERS OPTIONS

![]() Date printer

Date printer

![]() Tapping

Tapping

![]() N2 gas flush device

N2 gas flush device

![]() Zip open-close device

Zip open-close device

![]() Pouch pick-up position detection

Pouch pick-up position detection

![]() Stand-up pouch bottom opening device

Stand-up pouch bottom opening device

M3000 & M3550 DATA SHEET

|

Capacity : |

From 15 to 65 bags/minute (depending on the product) |

|

Bag type : |

• Flat, 3 or 4 sides with or without zip |

|

Bag width : |

100 to 230 mm (240 mm optional) |

|

Bag length : |

130 to 380 mm |

|

Weight capacity : |

From 150 grams to 1 kg (2 kg optional) |

|

Air consumption : |

0.5 MPa 600 NL/min |

|

Power supply : |

Phase 200V 8.2 kVA |

ANY QUESTIONS ?

OUR TEAM WILL BE HAPPY TO ANSWER THEM FOR YOU